A deep dive into AeroFarms : David Rosenberg, Co-Founder and CEO

By Paul Cuatrecasas on Thursday 1 April 2021

By Paul Cuatrecasas on Thursday 1 April 2021

Just last week, vertical farming specialist Aerofarms announced that it was going public through a merger with a blank check SPAC firm called Spring Valley Acquisition Group. Paul Cuatrecasas, CEO of Aquaa Partners recently caught up with AeroFarm’s David Rosenberg to discuss the technology behind vertical farming, closed loop agriculture and scaling up output to address a global market.

Last week’s deal puts a valuation of around $1.2 billion on the company (ticker ARFM) and will involve AeroFarms’ stockholders rolling 100% of their equity holdings into the new public company. The planned second quarter 2021 transaction is expected to provide up to $357 million in gross proceeds to AeroFarms – comprised of Spring Valley’s $232 million of cash held in trust, assuming no redemptions, and a $125 million fully committed PIPE at $10.00 per share, including investments from leading institutional investors, AeroFarms insiders, and Pearl Energy Investments, the sponsor of Spring Valley. By way of background, AeroFarms is both a commercial grower and a provider of indoor vertical farming services and cutting-edge R&D. The company's services include aeroponic growing systems for faster harvest cycles, higher-quality results, enhanced food safety, and less environmental impact, enabling local production without sun or soil in a fully-controlled indoor environment with sustainable farming practices. The company raised an undisclosed amount of venture funding from Abu Dhabi Investment Office on April 9, 2020. Previously, the company raised $100 million of Series E venture funding in a deal led by Ingka Group on July 9, 2019, which put the company's pre-money valuation at $400 million. Wheatsheaf Group, GSR Ventures, ADM Capital, AllianceBernstein and MissionPoint Partners also participated in the round. (source: PitchBook)

Paul Cuatrecasas

Hi David, let’s kick off with confirming some figures we have. AeroFarms is using advanced technology to grow produce, primarily leafy greens, with 95% less water than field farming, 40% less water than hydroponics, no soil, almost no land, less waste, effectively pesticide free and the product tastes amazing. The yield is about 300 times higher per square foot versus traditional farms annually. Is this an accurate representation?

David Rosenberg

The short answer is those numbers can be right however it depends on several factors. We grow a plant today in 14 days on the growing system. In our experience, that's usually like 18 to 20, 30, 40 days in other farms. The equivalent plant is about 30 days in a greenhouse, or 40 days in the field, something like that. We don't have to deal with seasonality (it’s too cold and plants don't grow or it's too hot and the plants don't grow). We get on average 26 crop turns a year, and the field farm, because of seasonality, might get 3. Then we grow on between 10 to 14 levels, vertically stacked in a controlled warehouse. The yield number of 300x you mentioned is based off of New Jersey farming of comparable plants where maybe there's one crop during the year, because it's just not the right environment to grow those kind of plants. However if you take it versus Salinas, for example, where we have a lot of plants growing and where it's three crop turns [per year], then it's 26 crops for AeroFarms versus 3 crops for field farming, and then AeroFarms is 12 to 14 levels high and year round. So, the over 300 yield is comparable for a field farm based on New Jersey, and compared to a filed farm based in Salinas the yield difference is about 130s. If you do it in Saudi Arabia where there's not much grown (because of lack of arable land and lack of water) you could say the yield is 1,000x greater or something like that, but ultimately it depends where you're growing. So, in other words, one acre at AeroFarms is the equivalent of up to 390 acres in New Jersey. When compared to organic, it’s even higher.

David Rosenberg

On the water side, that stat of 95% less water is true for some plants, but I don't want people to get hung up over that. Let's say we grow a new variety and it's not 95% less water, that doesn't mean it's a failure, there still could be a tremendous amount of value. So, we do use filtration, there are systems that can have dehumidification and water in closed loop systems. So, we could do these things and hit these water targets but it doesn't mean that's our must have, and it depends on the varieties. Different plants have different water needs, different sanitation requirements. So, I use the word up to 95%.

Paul Cuatrecasas

And regarding the AeroFarms produce, can you claim that it is completely pure of any type of chemical or pesticides, herbicides etc and that it is a “pure” plant?

The reason I ask is that more and more research is coming out that truly pure food, in which the staple ingredients such as wheat, rice, maize etc are completely free of herbicides, pesticides, and so on, can actually reduce and even eliminate diseases, which has a direct impact on health care costs. And if this were true, and if we agree that health care is one of the biggest problems in the West today, certainly in the UK and the US where it's probably the number one problem, over 20% of GDP, and if the majority of the costs are related to heart disease, cancer, diabetes, and so on, then a lot of this expense presumably could be dramatically reduced by the food we eat being pure rather than laced with chemicals? Can AeroFarms say, "we are part of that solution - we produce food that is pure and so we help solve this big problem"?

David Rosenberg

I believe that to be the case. We've never used pesticides, herbicides, fungicides. The misconception in the world is that “organic” equals pesticide-free, herbicide-free, fungicide-free. It's just not the case. I've seen striking numbers, even as much as 95% of all organics have pesticides, herbicides, fungicides, it's just organic pesticides, herbicides, fungicides. These are pesticides, and herbicides, some of which are very low toxicity and they’re not too bad for human health. Some of them have higher toxicity. Often the ones with lower toxicity aren't as effective for their purpose so people use tons more of it. You hear of river runoff and algae blooms and dead zones, I've talked to farmers who said the environmental impact is worse on the organics because they're putting a lot more pesticides on them because they’re not as effective.

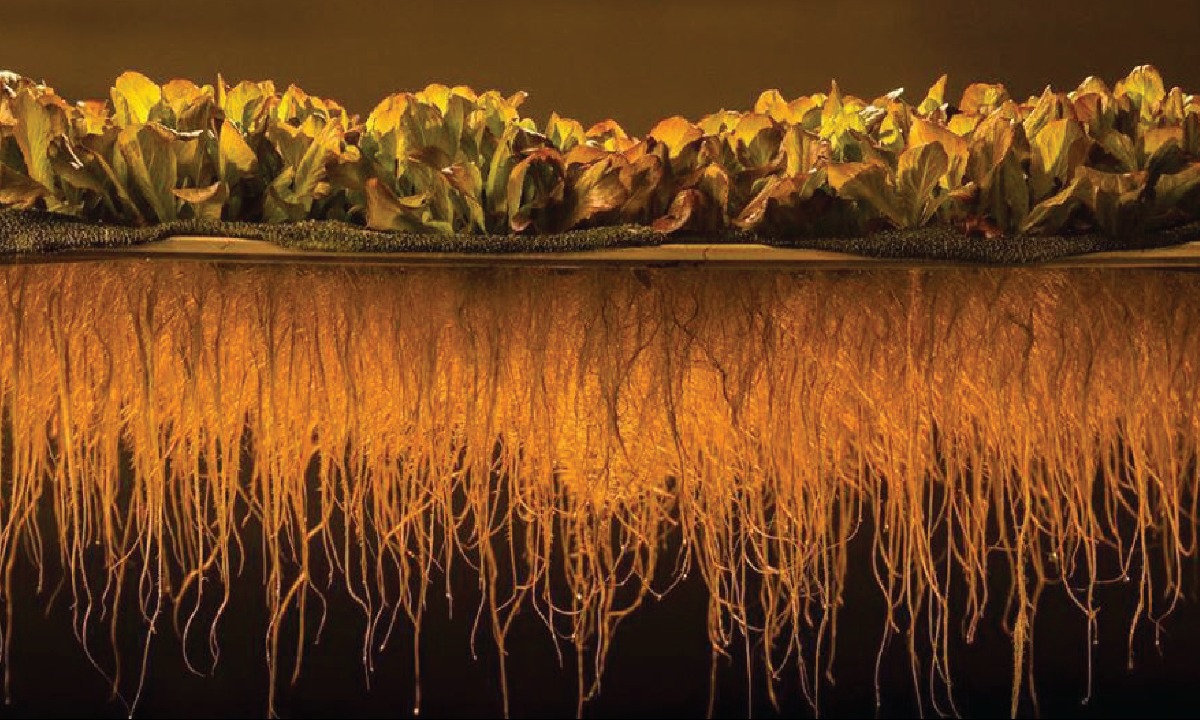

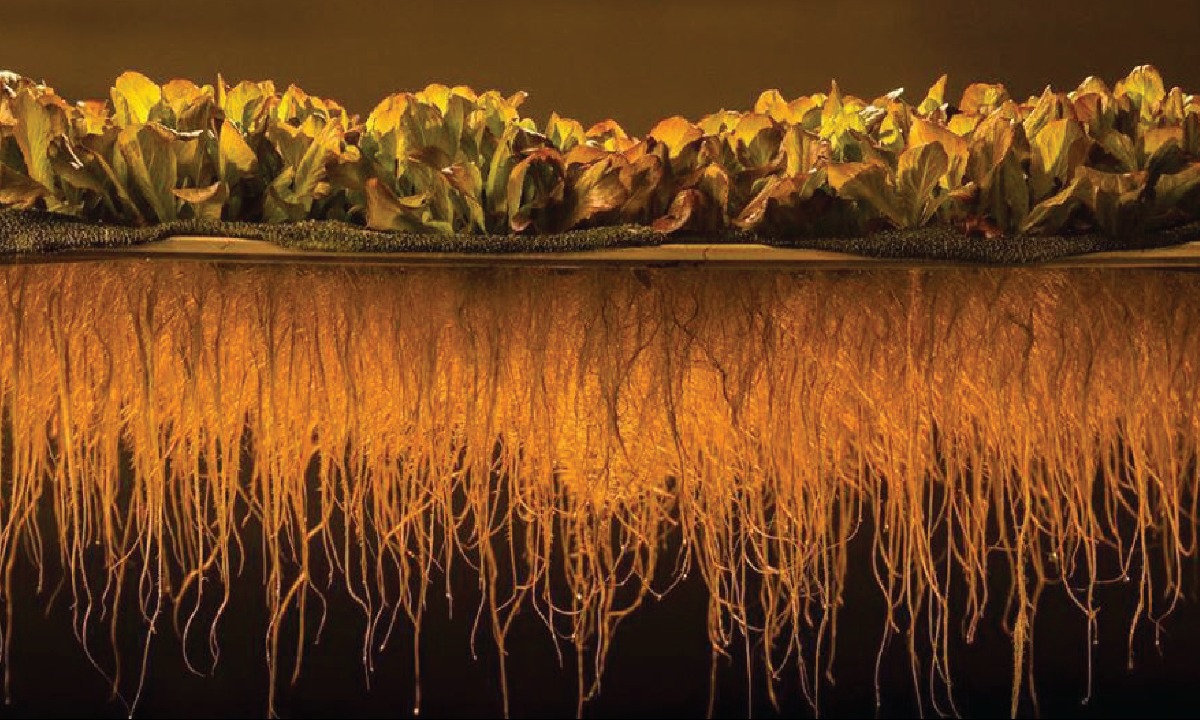

Copper, for example, is an active ingredient in organic pesticides - you don't want it in your body. These are not meant for human digestion. We've grown over 800 different varieties of plants without pesticides, herbicides, fungicides. If you buy product today at the supermarket, it's “triple wash.” People don't stop to think, “what does that mean?” But it means what it says, they wash it three times. If you go and look at what the wash looks like, after the first wash, it looks like milk. Literally that is the pesticides, herbicides, fungicides that are being washed off our food. You look at the second wash, it looks like watered down milk. The third wash still looks like watered down milk. We're digesting all this stuff. Then you wash it at home and there's still pesticides on it. In contrast, we at AeroFarms have a barrier to that. We spray a nutrient solution at the roots to get nutrients at the roots and the leaves (which is what people eat) stay completely pristine, and barriered from what the spray is down below (at the roots). The spray is the minerals and elements that are in soil and fertilizer.

Paul Cuatrecasas

Okay, so it's about as “clean” as you could get?

David Rosenberg

The leaves are pristine. There's nothing to wash off, there's no residue. I give it to my kids, they eat it right out of the bag like popcorn.

Paul Cuatrecasas

Do they love it? I mean, is it the taste? It just tastes great for them?

David Rosenberg

My 13-year-old eats it like popcorn, my 16-year-old eats it right out of the tray. It's the flavors. Our kale is the least bitter, most tender kale you've ever had. My biggest surprise is we used to think that we're competing on proximity to the store, and it turns out we're competing on taste and texture, and that's the benefit of fully controlled agriculture.

If you think of what a plant wants, I would argue that we at AeroFarms are understanding plants and their science to levels never achieved in human history. If you think about scientific discovery, you need to isolate a variable and test an assumption, and that's almost impossible to do in the field. In contrast, in a fully controlled agriculture, that's exactly what we do every time we grow.

So, to explain the understanding, imagine you're hungry, and I say, "go get food", versus if you're hungry and I say, "go get the Chilean sea bass with the broccoli, and complement it with the Chardonnay". It's like we are giving the plants just what they want, when they want it, how they want it, to influence, taste, texture, nutrient density, color, size, all these things. What you want as an adult is different from what a baby wants. So, we're understanding what they want at different maturities to optimize plant growth. So first to understand it in ways never achieved, and then to optimize it, and the net result is we're winning on taste and texture.

Paul Cuatrecasas

So the optimizing here can be done purely based on the environmental stressors?

David Rosenberg

Yes, think of it like the “nature versus nurture” argument. There's the genetic side, but then there's also the environmental side, i.e. what makes me who I am. So, it's the lighting, it's the temperature, humidity, airflow, CO2, pH, all these nutrients, micronutrients. And it's not just light, it's spectrum - intensity, frequency, all of those features, and that's why we're as much a data science company as anything else.

Paul Cuatrecasas

Because this is exciting to anyone who understands the attractiveness of what you're describing regarding the AeroFarms product and the possibilities, why aren’t the AeroFarms’ vertical farms everywhere? Is it purely the capital expenditure nature of the actual facilities, the LED lighting, etc.?

David Rosenberg

Capital has a lot to do with it, yes. It's a new industry. It's not like scaling up software. There is a capital intensity. In the US, we are great at deploying capital, but the investing gap is that relatively early stage companies that have a capital intensity could not get debt. Because if you look at debt, debt wants history, we don't have enough history yet. Without that history you need to use equity. From a returns standpoint, investing equity in R&D is great, and then rolling out projects is just harder to scale so you need a lot more equity. So, we need a lot more equity (at the moment) to build projects in different areas, and so that's very expensive. It's getting there and the cost curve is going down. Just think about the LEDs in your house. Five years ago, there weren't LEDs and now they're everywhere. We're innovating alongside of it, so our cost curve is continually going down, which makes the economics better, which makes the IRRs better. If we have more history, we'll be able to use more debt. Right now, we need more equity to deploy. We've already raised a few hundred million dollars and we'll be raising more. That's one of the challenges.

Paul Cuatrecasas

Are you also thinking about how you can leverage other advanced technologies such as AI, and you mentioned data science, but what about quantum computing (if that becomes available earlier than we think in four or five years)? Are you applying not just the lower cost of LED lighting and solar and so on, but also other advanced technologies as a whole package?

David Rosenberg

So the hard part about leading AeroFarms is the vertical integration. Hard might be the wrong word, but there's certainly a lot of thoughtfulness that goes into the vertical integration. We have engineering, mechanical, structural, lighting, electrical, PLC, process, industrial, design, all these engineers. On the plant science side, we have plant physiologists, pathologists, molecular biologists, microbiologists. All these people coming in to solve this problem. We do partner with a lot of parties. We have a partnership with Dell, for example….who would have thought Dell computers in farming? We have other partnerships with other big tech companies that we're not ready to announce today, but we've been collaborating with them for over a year and we may be announcing later this year. It's on the sensory side, it's on the imaging side, it's on the valves and the filtration. It's the nutrients, it's the genetics. The partnerships go on and on. There's a tremendous amount of collaboration. There's a big feeling internally at AeroFarms that's let's not reinvent the wheel. So how do we accelerate our innovation cycles? Who could we partner with to improve quality, lower capex, lower OPEX and grow more varieties?

Paul Cuatrecasas

You must want is to get this out to the whole world as fast as you can? Why wouldn't everyone want this out as fast as possible?

David Rosenberg

Yes. That said, the value proposition is stronger in some places than other places in the world. Look at solar. So with solar you had technology innovation in the US, and then you had early adopters, eg Germany and the US. And then as it scales up, you have a reduction in the capital cost, operating cost, and now you have distributed solar in Sub Saharan Africa. So, you focus as a businessperson on where's the early adopters. Where do you want to focus? For example, we're building a $100 million facility in Abu Dhabi, because our value proposition aligns with the challenges of that region, which is a lack of arable land, a lack of freshwater, and a large expat community that eats salads. We like the US market because it's an educated consumer. We go well typically if there's an educated consumer as they appreciate the differences of our product, and then the business model usually is strong.

Paul Cuatrecasas

So a key is that you need the educated consumer who will be more inclined to prefer to eat this food at a premium and the unit economics presumably depend on that so that there's very strong demand locally?

David Rosenberg

So today, for example, we sell in the category of “organic.” Organic has a 20% premium over non-organic, so we're selling at the same price as the organic field farmer, and we currently need that premium. In some parts of the world, people aren't aware of asking for that premium. So, that doesn't have to be our first stop, it could be our third stop. Some parts of the world, people don't eat salads, so that's hard to change behavior. So, let's go to places where people eat salads, and they're asking those sorts of questions.

Paul Cuatrecasas

So, my understanding is that today you're producing leafy greens, mainly. With the aeroponic technology can you do more than a couple of varieties? Can you combine aeroponic with hydroponic to be able to do more?

David Rosenberg

So, we're very agnostic in the sense that we don't care. The ‘Air’ in Aerofarms uses aeroponics and that's the genesis of the company. But we tell people we don't care. Roots want oxygen, leaves want carbon dioxide. So, depending on the root physiology, there are different ways to oxygenate and get nutrients to the roots. We've tried 120 different types of ways to deliver nutrients to the root structure, and about 80 different types of growth media to support different types of plants. We've grown about 850 very different types of plants. It starts off with a plant scientists saying, "this is what we think a plant wants", and then all these other people around them saying "this is the best way to deliver it". We grow some plants, hydroponically, some plants aeroponically. We do whatever is best for the plants. The answer is we do both. For leafy greens we believe the better solution is aeroponics, we see improvement in quality and a shorter growth cycle.

Paul Cuatrecasas

And so leafy greens is the main product, are there others? Are there other vegetables or other products apart from leafy greens that are being produced today?

David Rosenberg

We're very bullish that we're going to improve our ability to scale and add more crops over time. Alongside the leafy greens or fruits and vegetables, it's also on the seeds. It's on the genetics. We're adding value to the broader agriculture, and we're doing that today in public.

Paul Cuatrecasas

Can you say then that the ambition over time is for AeroFarms to become more of a complete agricultural company delivering all types of vegetable and fruit products?

David Rosenberg

Yes, we've grown over 800 different varieties of plants, and very different types of plants. One of the public elements of this effort is something called the Foundation of Food and Agriculture Research (FFAR) PIP Consortium “precision indoor plants” - for which AeroFarms is the principal investigator. Basically, we're the project manager of this group of 8 companies, including BASF, who are all doing their genetic work at AeroFarms. We're not just working with the seed brokers, we're working with the seed breeders on optimizing genetics. That's a whole other conversation in and of itself.

Paul Cuatrecasas

What would you say the biggest challenges that you feel, David, in growing the business the way you want today? What's the thing that keeps you up at night?

David Rosenberg

Nothing really, [we're] very bullish about the industry. There's always concerns with scaling too fast. Maintaining the right culture is important as the company grows. For example, with one recent job posting we had 9,000 applicants. Another job posting, we had 2,000 applicants. We have a bunch of people from MIT, who before coronavirus they went to a job fair, and they said the line for talking with AeroFarms was longer than the line to talk to Facebook.

There's a lot of excitement, but always there's so many different problems to solve. The partnerships, the vertical integration, there's a lot of complexity. We have great people. AeroFarms has put a lot of thoughtfulness into food safety. I think, in the industry, a lot of people read about AeroFarms, get excited and think "Oh, it's simple. I'll have a light and a potted plant, and I could be a vertical farmer". They're not putting as much thoughtfulness into it, and I actually think a lot of them are going to go out of business or there could be a food safety concern that puts a bad sentiment on the industry. So that's a concern. If you look at the macro trends and the technology trends, it's going to be a big industry. And it's going to be successful, but I think there's going to be a couple tough rides for some people along the way, which could have a bad message for the industry.

Paul Cuatrecasas

Regarding strategic partners, I see IKEA on the cap table. Are these types of corporate investors a distraction for you at the moment? Because you mentioned the complexity, the culture, etc…there's so much going on? The larger incumbents across the industry, who over time will become more attracted to you and to your model, and to others as well. But it seems like perhaps that would be more of a distraction at the moment to be talking with them? Do you just need to get on with what you're doing and then perhaps in a year or two over time that becomes more relevant?

David Rosenberg

Well, we actually we have a lot of strategic partners that we work with it. We haven't seen that value in collaborating with the big field farmers as much, but we collaborate with distributors and big people in the ag tech space. A lot of them are confidential, but they're the biggest names in agriculture that we collaborate with, in a host of ways. We collaborate with like some of the biggest CPG companies in the world. There are tons of strategic partnerships with regional players. For a company of our size, we probably have as many partnerships as anyone could imagine.

Paul Cuatrecasas

And in terms of strategic investment…?

David Rosenberg

More of it's been regional, like you mentioned IKEA but also Dubai Holdingsto help us get into the Middle East. Also Grosvenor Estate’s Wheatsheaf Group, they have a strong presence in the UK. So, we've focused on regional and we focus on long term investors.

Paul Cuatrecasas

In terms of distribution and getting the product to market, once you have the facilities in a region, is the B2C / supermarket partner model a way to go like it appears you've done so far in in the New Jersey area?

David Rosenberg

Yes, when you say B2C, we sell to supermarkets, then supermarkets sell to the consumer. So, we're on the shelf. I think the hub and spoke model and to sell it to a supermarket makes more sense than direct B2C. We also sell to food service. We've realized we have a strong brand, so we lead with the brand. So, the target markets are supermarkets and food service.

Paul Cuatrecasas

Thanks David, it’s such an exciting story. We could talk for hours no doubt, and I appreciate the time you’ve taken to share your views with our community and look forward to talking again soon.

2 August 2021

Paul Cuatrecasas

13 September 2021

Paul Cuatrecasas

30 June 2021

Paul Cuatrecasas

9 September 2021

David Stevenson